Fast Forward: How Rapid Prototyping Drives Innovation in the Tech World

The world of technology is rapidly evolving, and with the advent of the Internet of Things (IoT), there is a growing need for efficient and effective prototyping methods. Rapid prototyping has emerged as a powerful tool that enables tech developers to quickly iterate and validate their ideas, bringing innovative solutions to the market faster than ever before. We have talked to Tristan Steindor, Director of Product at NBT, to discuss its benefits, process, and best practices for IoT. Read more about the concept of rapid prototyping and how NBT can support you in that matter.

From Ideas to Reality: Accelerating IoT Innovation with Rapid Prototyping

Rapid prototyping is an iterative design approach that allows IoT developers to quickly build and test their concepts. It involves creating a tangible representation of an IoT product or system, allowing for early feedback and validation. By using rapid prototyping techniques, developers can identify design flaws, explore different possibilities, and make informed decisions to enhance the functionality and user experience of their IoT solutions.

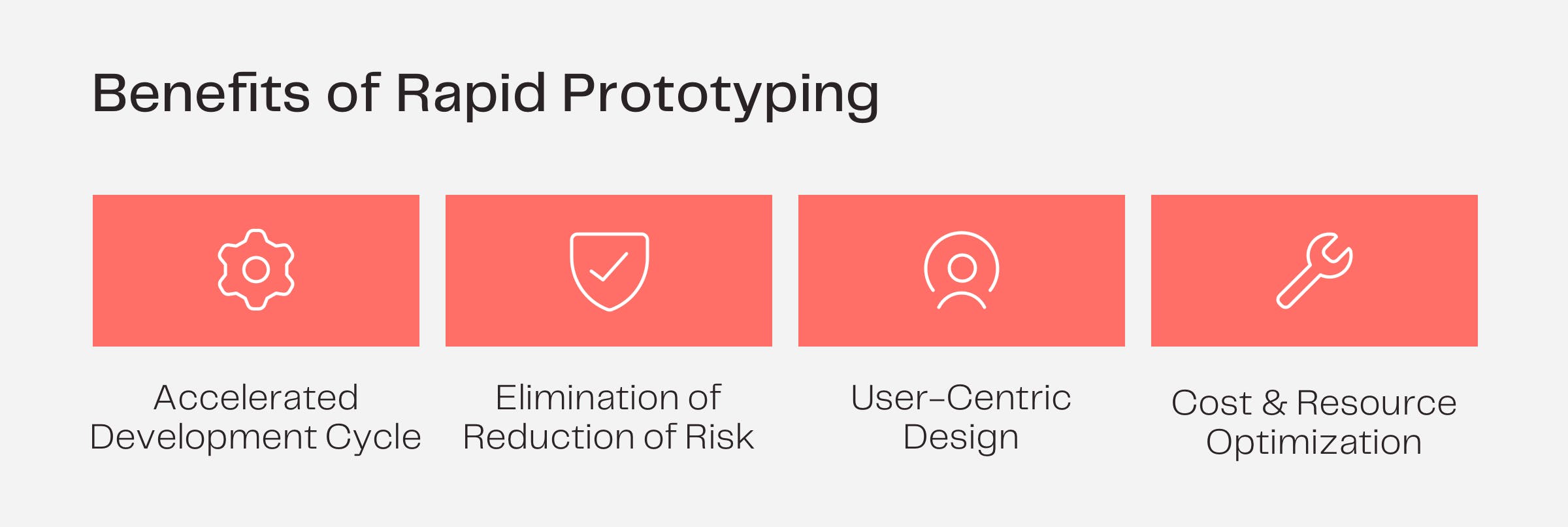

Benefits of Rapid Prototyping in IoT Development

Rapid prototyping offers numerous benefits in the development of IoT solutions. Some key advantages include:

Accelerated Development Cycle

Rapid prototyping enables developers to reduce the time required to bring their IoT ideas to life. By quickly building prototypes and gathering feedback, developers can iterate and refine their designs, shortening the overall development cycle.

Elimination or Reduction of Risk

The process allows developers to quickly create tangible prototypes and test them extensively. By doing so, they can identify design flaws, usability issues, and potential risks early in the development cycle. This early identification helps in mitigating risks before they become major issues in the final product.

User-Centric Design

Through rapid prototyping, developers can involve end-users in the design process. By obtaining early feedback and understanding user requirements, developers can create IoT solutions that are tailored to users' needs, leading to improved user satisfaction.

Cost and Resource Optimization

Rapid prototyping helps identify design flaws and usability issues at an early stage, reducing the risk of costly mistakes during the later stages of development. It allows developers to optimize resources and allocate them efficiently, resulting in cost savings.

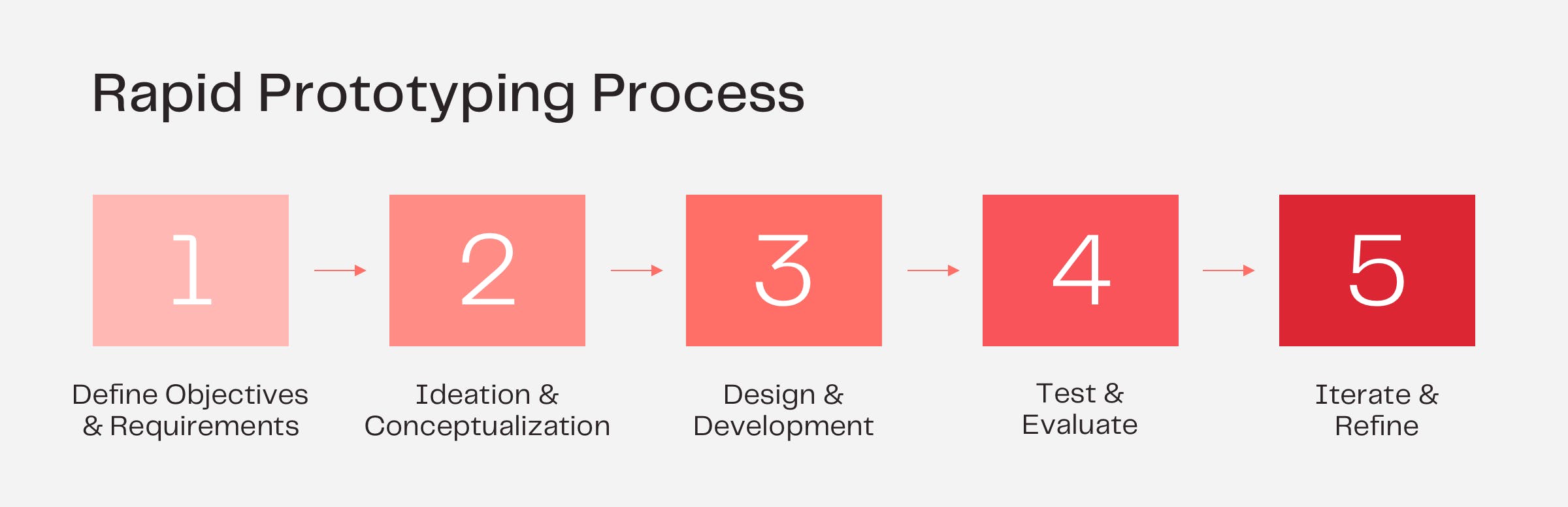

From Vision to Reality: Mastering the Steps of Rapid Prototyping for IoT Success

Tristan and his team usually pursue the following steps in order to achieve a prototype or a Minimum Viable Product (MVP).

Step 1: Define Objectives and Requirements

The first step in rapid prototyping is to clearly define the objectives and requirements of the IoT solution. To be able to do so a deep understanding of the underlying problem and how it impacts the affected ecosystem is necessary. Based on that you can derive user needs, and define desired features and functionalities.

Step 2: Ideation and Conceptualization

In this stage, developers brainstorm ideas and explore different concepts for the IoT solution. They may sketch rough designs, create user flows, and map out the interactions between various components.

Step 3: Design and Development

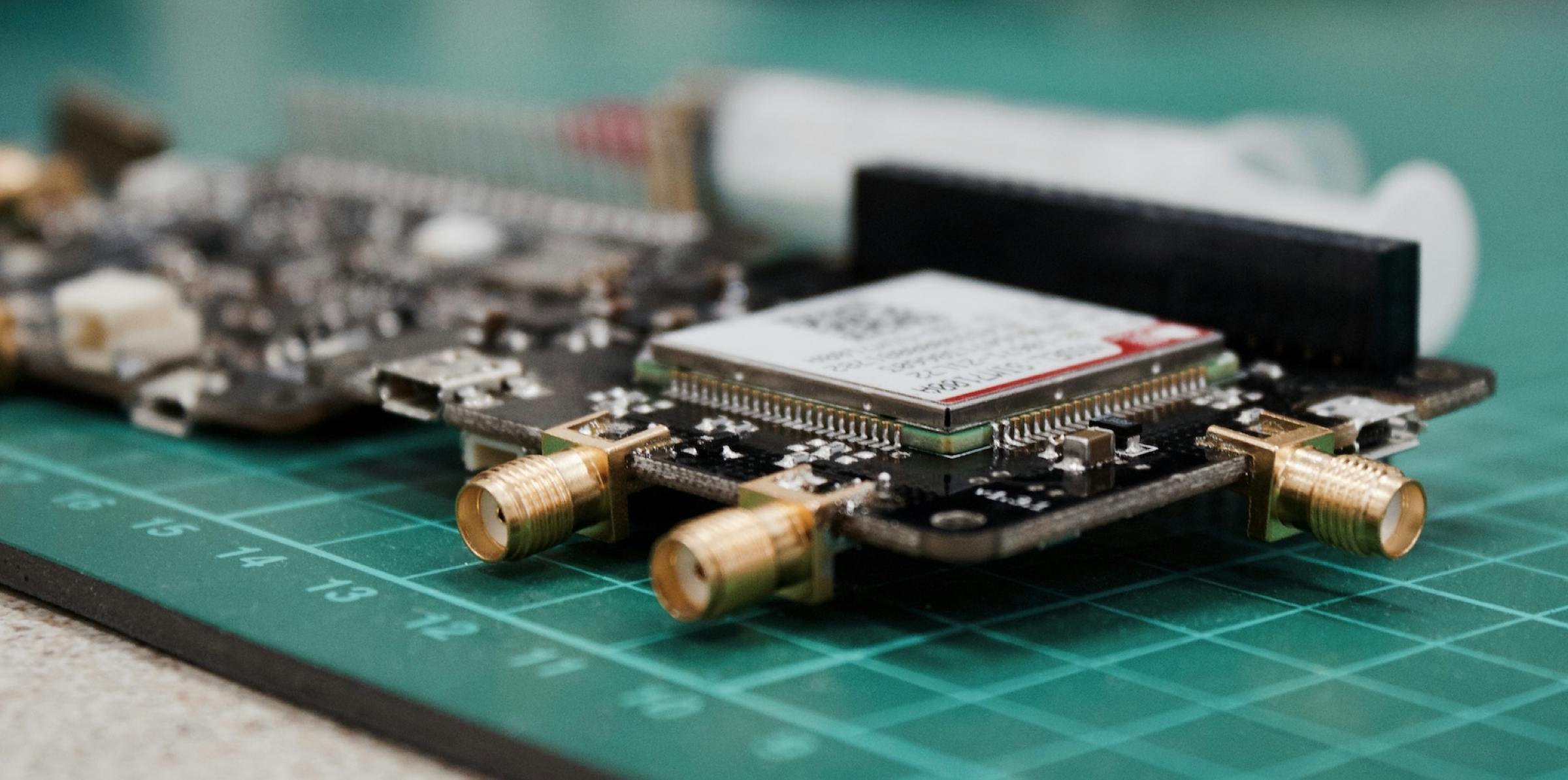

Once the concepts are finalized, developers move on to designing and developing the prototype. This involves selecting the appropriate hardware and software components, integrating them, and creating a working model of the IoT solution.

Step 4: Test and Evaluate

The prototype is then tested and evaluated to gather feedback and identify any areas for improvement. User testing and feedback play a crucial role in refining the design and enhancing the user experience.

Step 5: Iterate and Refine

Based on the feedback received, developers iterate on the design, making necessary modifications and enhancements. This iterative process continues until the prototype meets the desired objectives and user requirements.

Accelerating Innovation: Mastering Best Practices for Successful IoT Rapid Prototyping

To ensure successful rapid prototyping in IoT development, consider the following best practices:

Clear Communication and Collaboration

Effective communication and collaboration among team members are essential for rapid prototyping. This includes regular meetings, clear documentation, and a shared understanding of the project goals.

Agile and Iterative Approach

Adopting an agile and iterative approach allows developers to quickly adapt to changing requirements and continuously improve the prototype. It promotes flexibility and encourages regular feedback from stakeholders.

Use of Rapid Prototyping Tools

At this point, Tristan explicitly refers to NBT’s Machine Economy Platform (MEP). "With our existing capacities and expertise in development, founders don't have to reinvent the wheel with us every time. Whether it's product, hardware or software, our lab allows rapid prototyping to be applied in any field."

Navigating Challenges: Overcoming Hardware Limitations and Security Issues

While rapid prototyping offers numerous benefits, there are some challenges that developers may encounter. Some common challenges include:

Hardware Limitations

Selecting the appropriate hardware components and dealing with their limitations can be challenging. Developers need to carefully consider factors such as power consumption, connectivity options, and compatibility with other devices.

Scalability and Security

As IoT solutions scale, ensuring the security and scalability of the prototype becomes crucial. Developers need to design robust architectures and implement security measures to protect data and ensure seamless operation.

Case Studies: Successful Applications of Rapid Prototyping in IoT

In the industrial sector, rapid prototyping has facilitated the development of IoT solutions for process optimization, predictive maintenance, and remote monitoring. It has helped businesses improve efficiency, reduce downtime, and enhance overall productivity. Tristan refers to three use cases from NBT’s ventures:

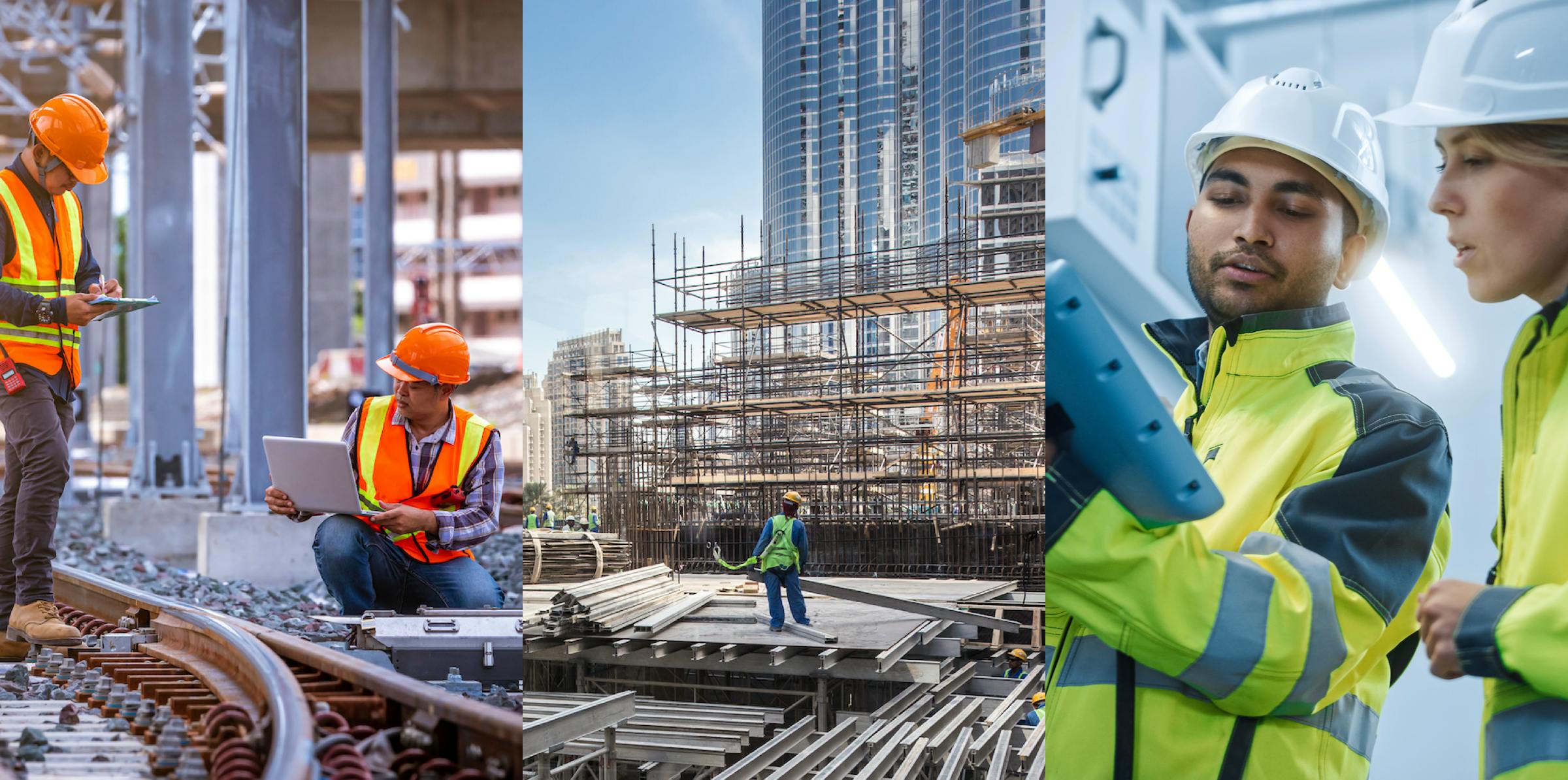

Predictive Maintenance for Railway Infrastructures

“We have currently developed the IoT system for AXO Track together with their founder Oliver von Sperber. It facilitates the maintenance of critical railway infrastructure by providing real-time data on the status and conditions of assets such as switches.

We designed the hardware via our rapid prototyping process in less than 9 months and got it to the track in real-world use. We also developed an application based on our Machine Economy Platform in parallel that couples devices in the physical world with the digital world, making them uniquely identifiable and indicating their location in the field.

With the application, AXO Track is able to do a mass rollout of devices in the field in a coordinated manner via a standardized process. This not only improves the technical process but at the same time also optimizes the business purpose in such a way that within a short period of time, the speed from the idea to the technical realization to the real deployment has been massively accelerated. This results in very effective ventures that can be quickly positioned in the market.”

To Oliver, even though he is experienced in the field of IoT sensors, the collaboration is very fruitful: “Technical expertise is hard to find. However, NBT has it all. NBT has an excellent technical team and a ready-equipped lab to build business case prototypes and MVPs.”

More Efficiency and Safety through Concrete Monitoring

ConcR is an intelligent IoT solution for monitoring concrete quality in real time to be more efficient, faster, and reliable. Construction time can be shortened by up to 30% while reducing costs by up to 20%.

The solution also derives from NBT‘s Machine Economy Platform and is powered by cellular IoT hardware from Nordic Semiconductor. Nordic‘s nRF9160 system-in-a-package offers up to 15 years of battery life and covers computer processing, navigation, and LTE-M/ NB-IoT communications modes.

Dr. Burak Acilan, CEO & Founder of ConcR, explains his solution: “One set includes a small wireless transmitter and a high-precision DS18B20 digital temperature sensor. The sensor can easily be attached to the foundation, formwork, or reinforcement to continuously measure the hydration temperature and ambient temperature, providing information about concrete strength. The device also has an additional temperature node on the housing itself, allowing for more precise measurements. The temperature sensor is connected to the transmitter using an IP67 connector. Data is transmitted to the ConcR portal in the cloud via cellular communication using NarrowBand IoT (NB-IoT) or LTE for Machine Type Communication (LTE-CatM), depending on local availability.

Our ConcR R-Series is designed to meet the specific requirements of concrete production and can withstand challenging site conditions. It has a measurement accuracy of ±0.5°C in temperatures ranging from -10°C to +85°C and utilizes the HFSS Engineering Simulation Software from Ansys.

Read ConcR’s Case Study

Improving Machine OEE through Advanced Analytics

Makula has developed a proven, existing system that enables SMEs, OEMs, machine suppliers, and distributors to digitalize their after-sales services and thus have the chance to monetize them. Comprehensive after-sales services form a significant part of the value chain and are considered one of the most important competitive advantages for machine manufacturers and distributors.

One of the many features of Makula’s platform allows Machine Resource Management: “The digital life cycle of each machine with its respective documentation and work order is stored in one place. The access to maintenance and/or spare part orders and other relevant information, from sophisticated 3D models to video tutorials, works simply by scanning a QR code”, explains Emkay Khan, CEO and founder of Makula. “Our goal is to enable machine suppliers to focus on what really matters – profitability & customer experience. With the variety of features and the simplicity of use, our platform is unique on the market.”

Read Makula’s Case Study

Shaping the Future: Exploring Emerging Trends in Rapid Prototyping

The future of rapid prototyping for IoT looks promising. Tristan sees some emerging trends including:

3D Printing

Advancements in 3D printing technology are revolutionizing rapid prototyping. It allows developers to create physical models of IoT devices and components, enabling more realistic testing and validation.

AI Integration

Artificial intelligence (AI) integration in rapid prototyping can further enhance the capabilities of IoT solutions. AI-powered algorithms can analyze data collected by prototypes, identify patterns, and provide valuable insights for optimization.

Shaping the Future: Exploring Emerging Trends in Rapid Prototyping

Rapid prototyping is a game-changer in the development of IoT solutions and has become an indispensable tool for developers seeking to bring their innovative ideas to life. By enabling quick iteration and validation, rapid prototyping accelerates the development cycle and ensures user-centric design.

If you have a deep tech idea, you can leverage rapid prototyping to create robust and successful IoT solutions through the adoption of best practices and the ability to overcome challenges. Embrace this iterative and agile approach. It will undoubtedly pave the way for groundbreaking advancements in the realm of the Internet of Things.

Do you need technical support? Don’t hesitate to get in touch with us. Our Visionaries Program could be made for you!

FAQs About Rapid Prototyping

- How long does rapid prototyping typically take for an IoT project?

The duration of rapid prototyping varies depending on the complexity of the IoT project. It can range from a few weeks to several months, depending on the objectives, requirements, and resources available. - Is rapid prototyping only suitable for software-based IoT solutions?

As the term "Rapid prototyping" was born for hardware development, it can of course be used for hardware-based IoT solutions. In fact, it is highly beneficial for hardware prototyping as it allows designers and engineers to quickly build and test physical prototypes of IoT devices. By creating tangible models, they can evaluate the form, fit, and function of the hardware components, make necessary adjustments, and ensure optimal performance before moving on to mass production. Therefore, rapid prototyping is a versatile approach applicable to both software and hardware aspects of IoT development. - Can rapid prototyping be used for both hardware and software-based IoT solutions?

Yes, rapid prototyping can be used for both hardware and software-based IoT solutions. It allows developers to test and validate the integration of hardware components, as well as the functionality and user experience of software applications. - How does rapid prototyping contribute to the success of IoT projects?

Rapid prototyping plays a crucial role in the success of IoT projects by enabling early validation of concepts, identifying design flaws, and gathering user feedback. It helps in reducing development time, optimizing resources, and delivering IoT solutions that meet user expectations. - Are there any limitations to rapid prototyping for IoT?

While rapid prototyping offers numerous benefits, it also has some limitations. A system that is typically designed this way is not intended to be used in a productive environment although it already fulfills the user's needs. After this process, some steps need to be taken to achieve complete market readiness.